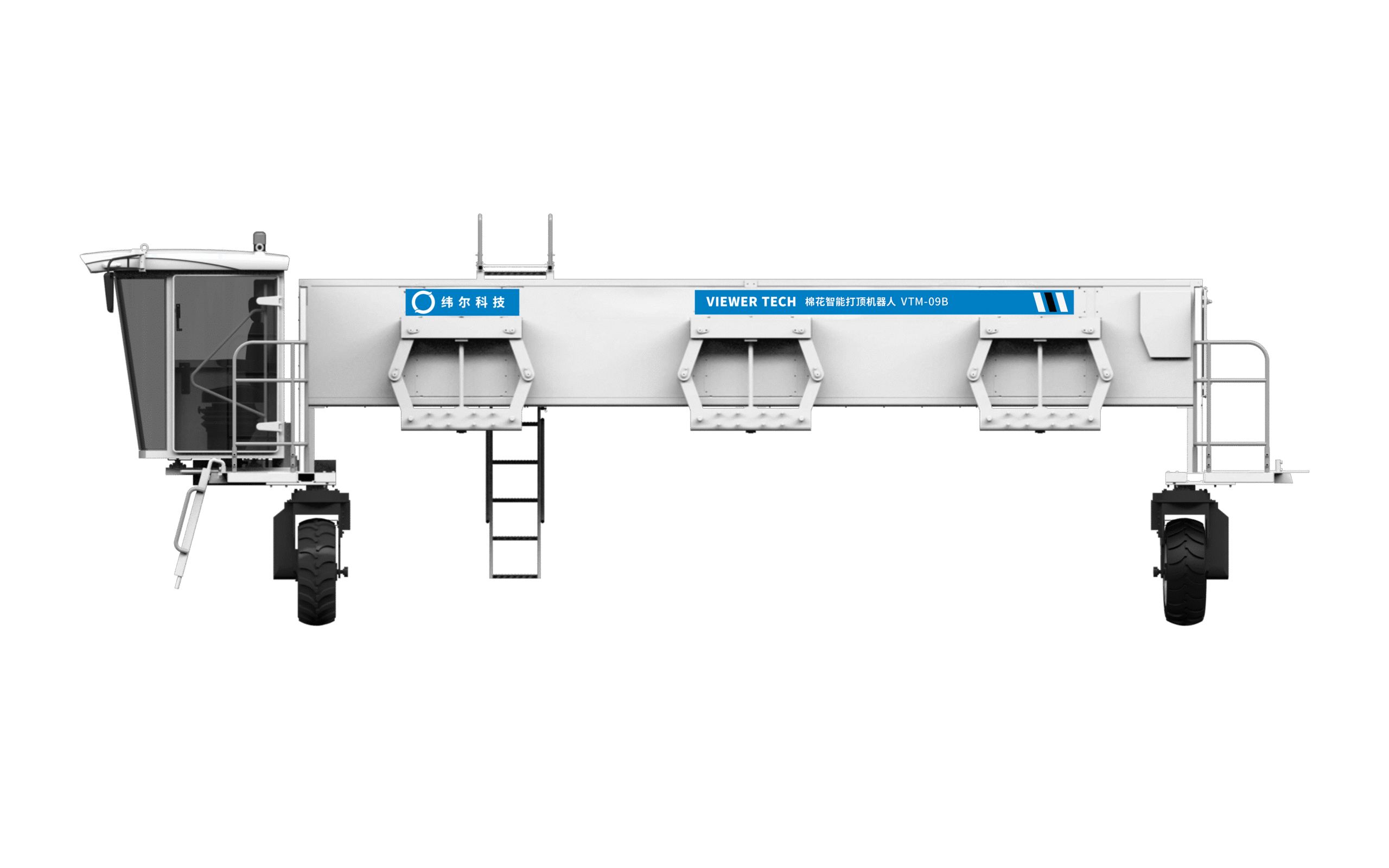

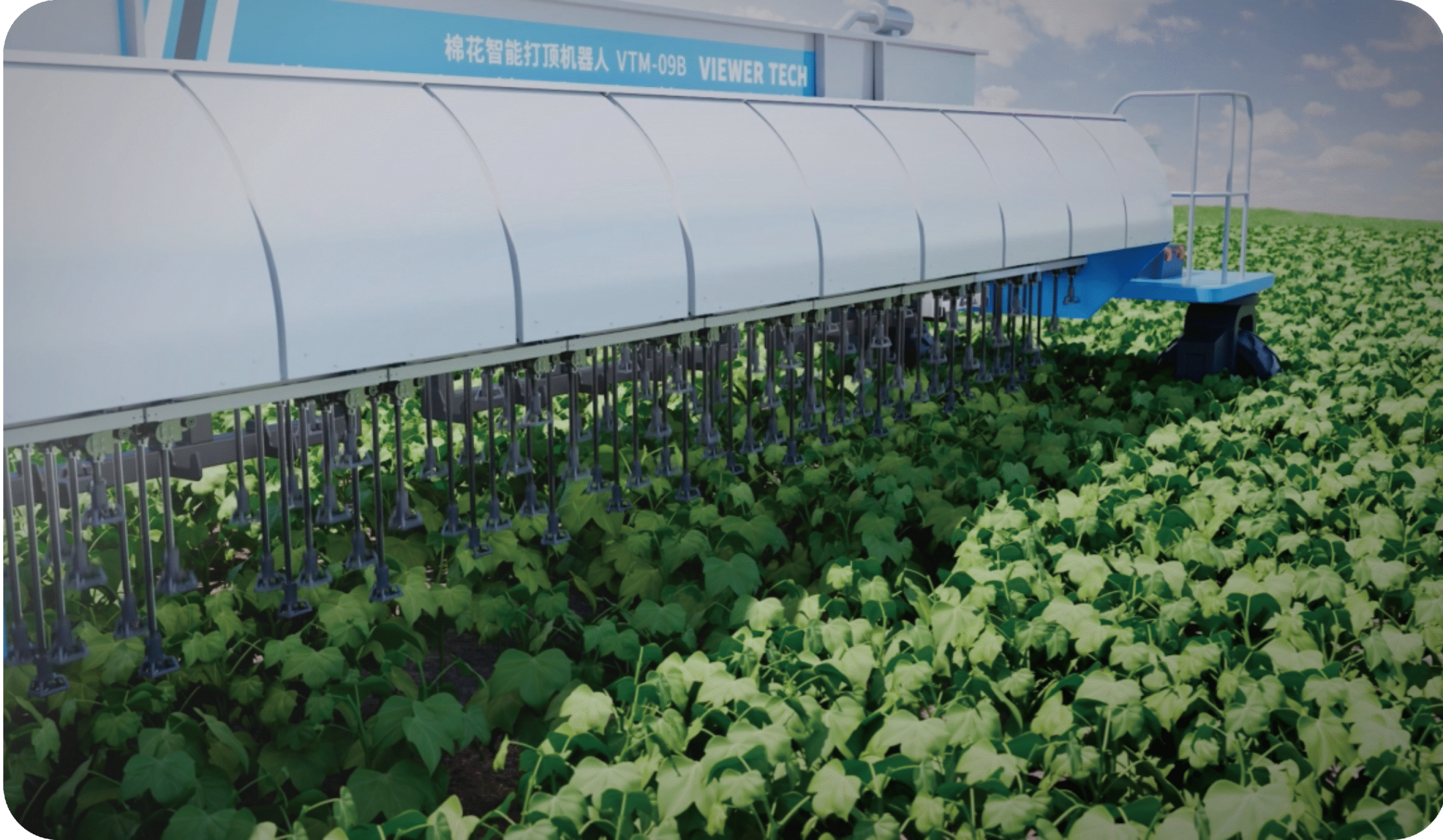

The Cotton Topping Intelligent Robot VTM-09B is a fully autonomous agricultural robot designed specifically

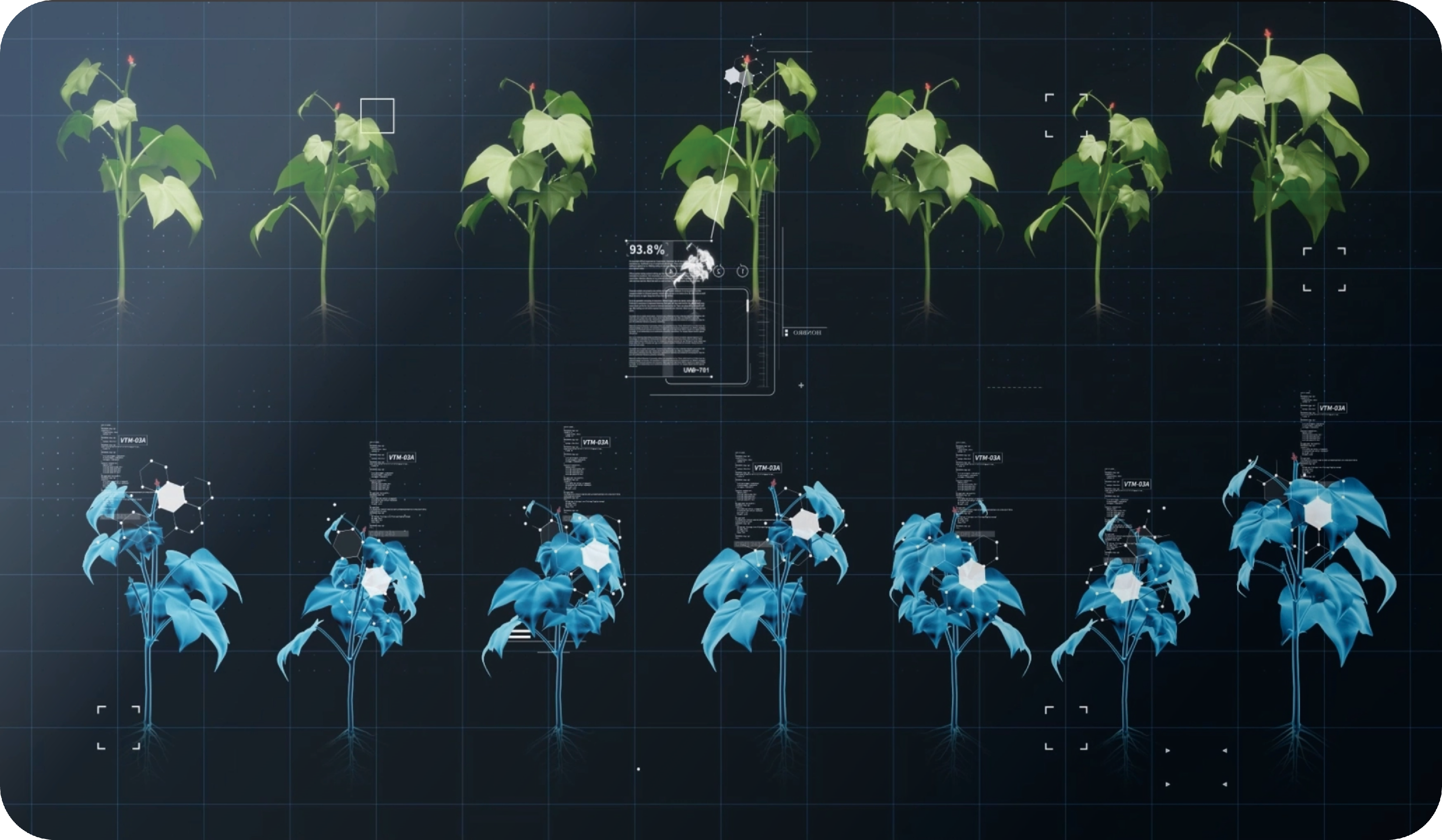

for cotton cultivation. Equipped with advanced sensors and machine vision, it can accurately identify cotton

shoot tips and simulate manual topping operations, achieving efficient and precise performance. Powered by

agronomic large models and real-time environmental perception, it dynamically adjusts topping strategies and

operates reliably even at night, effectively alleviating labor shortages during peak farming seasons.

for cotton cultivation. Equipped with advanced sensors and machine vision, it can accurately identify cotton

shoot tips and simulate manual topping operations, achieving efficient and precise performance. Powered by

agronomic large models and real-time environmental perception, it dynamically adjusts topping strategies and

operates reliably even at night, effectively alleviating labor shortages during peak farming seasons.

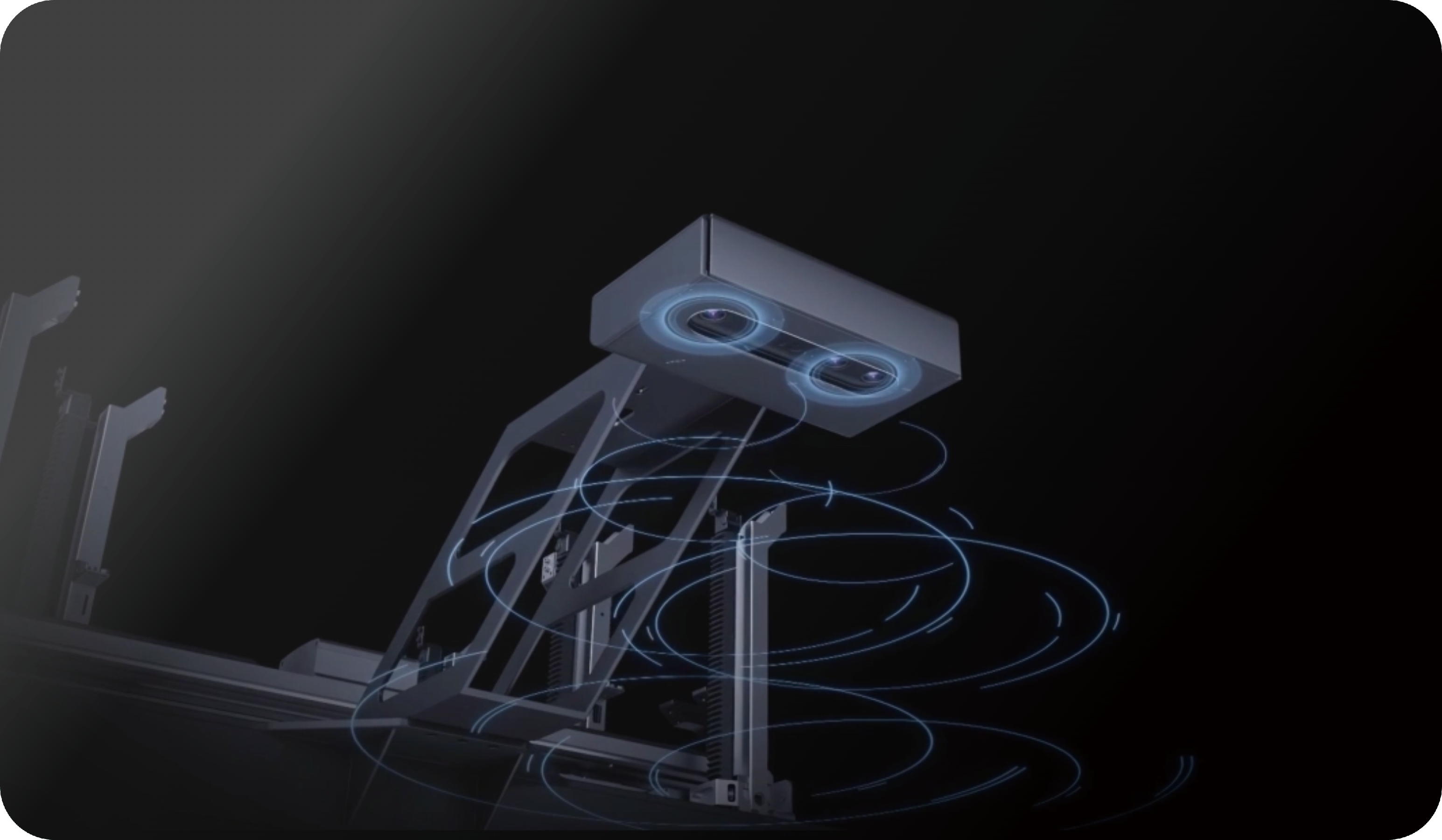

Human-like Binocular Vision

AI Planning Algorithm

Precision Positioning

One-Click Start

Compact Overall Architecture

Dual Smart Display

24-hour Operation

High-speed Operation

Module Mounting · Intelligent Control of Single Plant · Precision & High

Efficiency · Easy to Operate