Viewer Technology’s intelligent cotton topping robot is the world’s first fully self-developed intelligent robot, integrating “binocular vision 3D reconstruction + AI planning algorithm + precision operation control technology.” It is designed for topping cotton in leveled fields, simulating manual topping actions to achieve high precision and efficiency.

Equipped with a binocular vision 3D camera and a high-performance deep learning processor, it uses AI planning algorithms to accurately and strictly perform the “two leaves and one heart” topping technique, significantly reducing planting costs and technical barriers, and maximizing both agricultural execution and per-acre economic benefits.

Equipped with a binocular vision 3D camera and a high-performance deep learning processor, it uses AI planning algorithms to accurately and strictly perform the “two leaves and one heart” topping technique, significantly reducing planting costs and technical barriers, and maximizing both agricultural execution and per-acre economic benefits.

Human-like Binocular Vision

AI Planning Algorithm

Precision Positioning

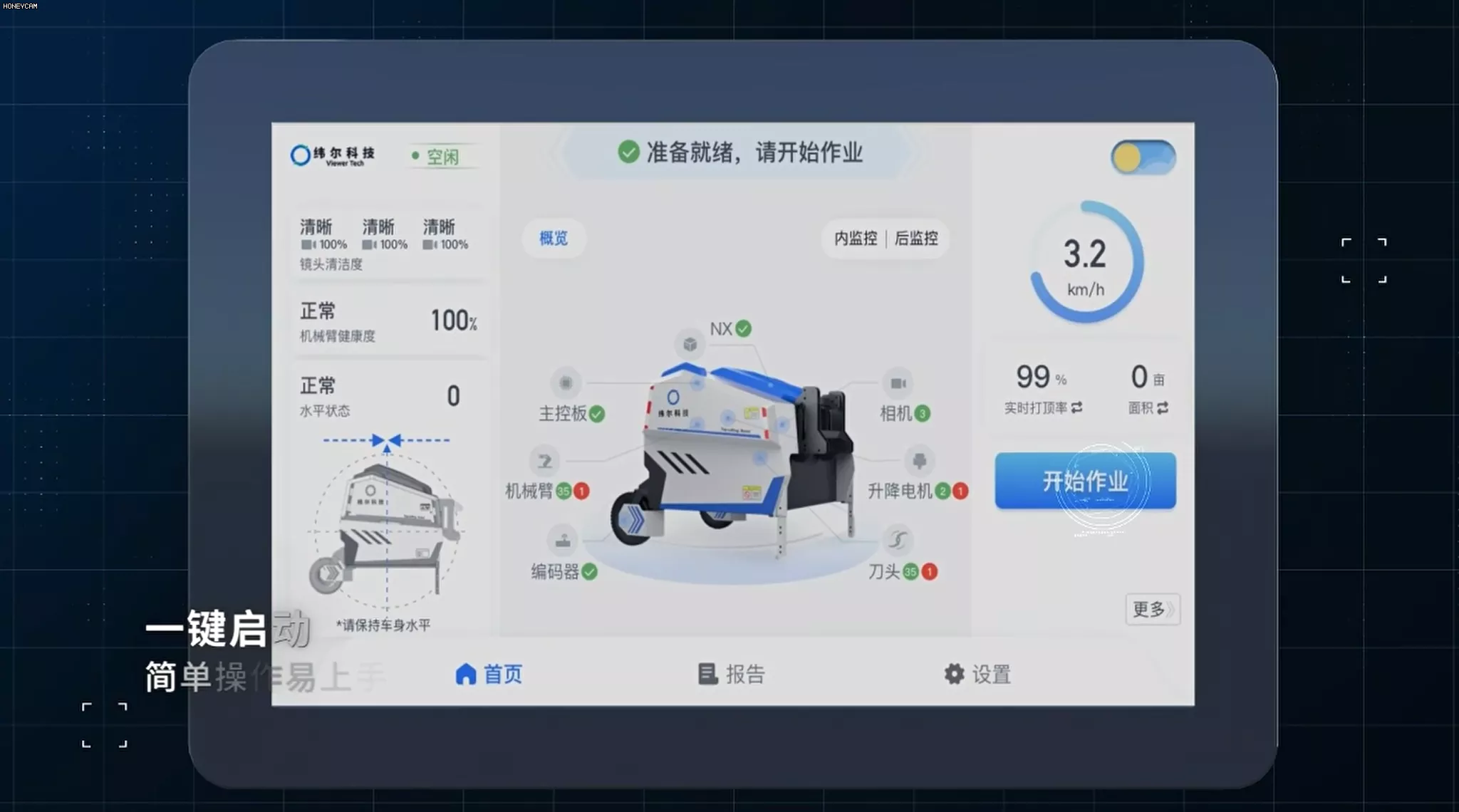

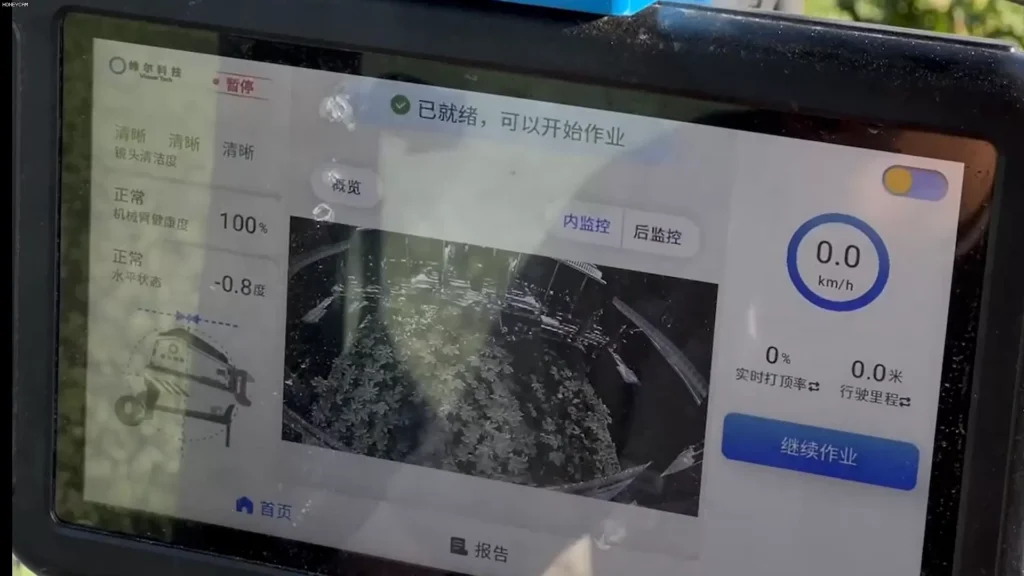

One-Click Start

Compact Overall Architecture

Dual Smart Display

24-hour Operation

High-speed Operation

Precise removal of cotton plant top buds and leaves

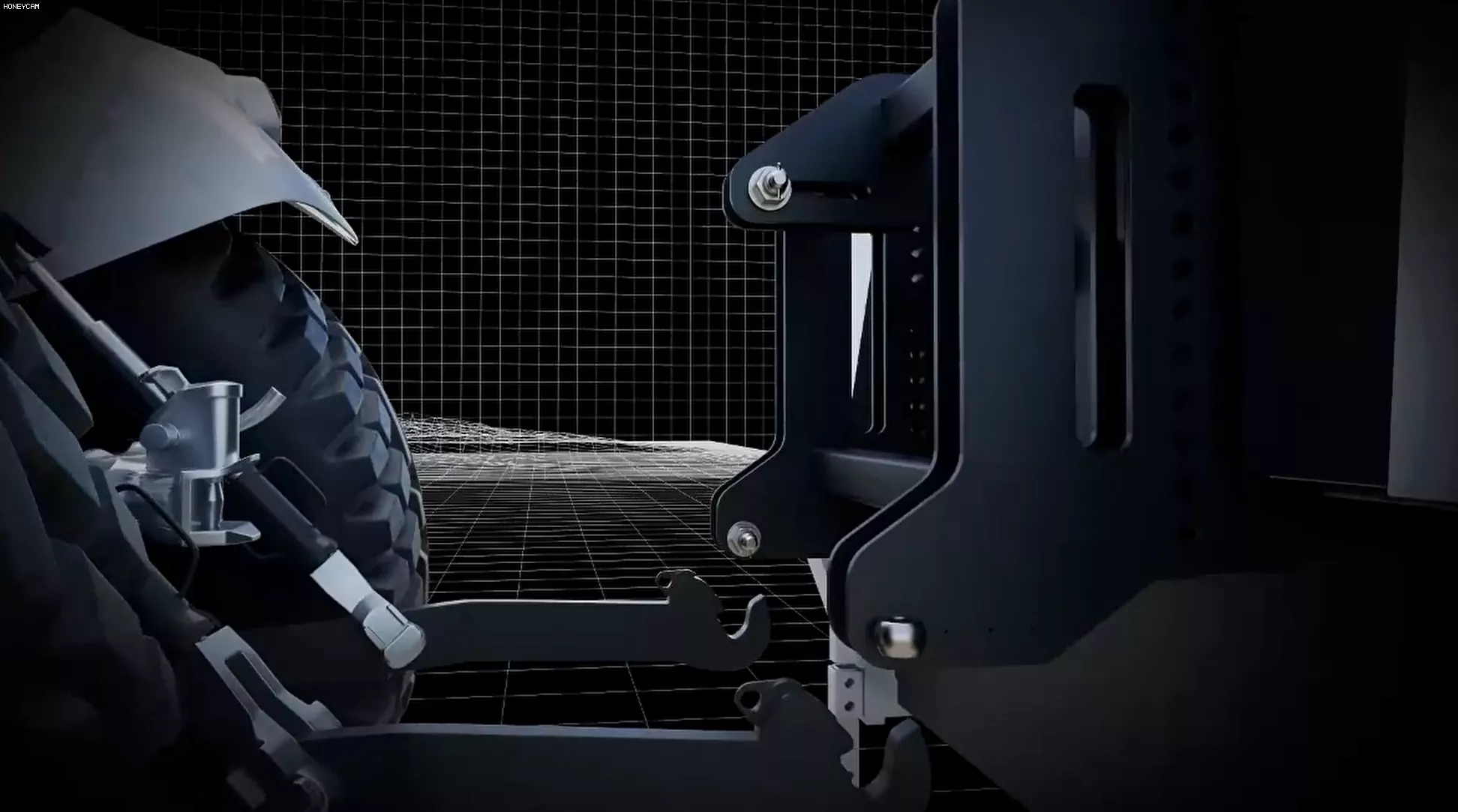

Using vision detection and image recognition sensors, combined with a servo-controlled vertical cutting and lifting system, it can precisely detect the cotton top position and perform accurate topping under complex field conditions.

Easy Cutting at Different Heights

The system uses binocular vision 3D sensors to determine the height of the cotton heads, driving the high-speed rotating cutter to raise or lower accordingly, ensuring precise topping for cotton with varying growth conditions across different fields and varieties.